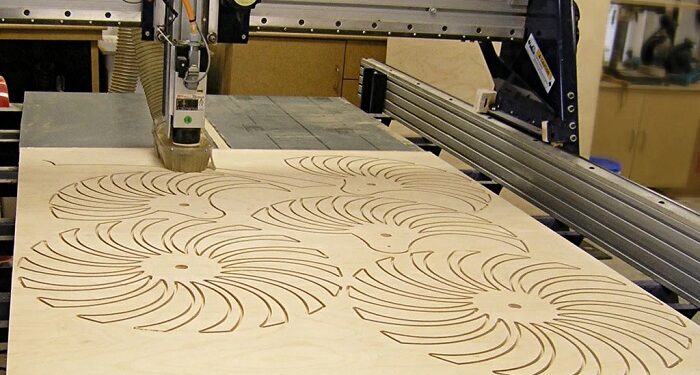

Modern materials very often replace expensive solid wood with cheaper varieties. One of such options is MDF. These layered sheets can be used in various fields of human activity, but their cutting requires precision and accuracy to avoid defects. MDF cut to size board is offered by a specialized company.

Characteristics of the work performed

For private and corporate customers, the Easy Spray company offers services for cutting sheet materials based on wood. It can perform any type of cutting or processing of MDF, oriented strand plywood OSB, fiberboard, chipboard, and other similar materials.

Customers can be manufacturers of furniture, products from similar materials, these can be companies or individual clients.

The company carries out the following types of work:

- A wide variety of materials are processed, which are created on the basis of wood fibers, chips, veneer, glue and pressing are used as a connecting composition.

- In addition to cutting, drilling and grinding can be performed.

- The work is carried out on CNC machines in automatic mode. It is possible to process sheets of different sizes, the result can be parts of any size and configuration.

- The work is carried out by experienced specialists who know all the features of the materials and are able to perform the most complex type of processing.

Orders of any volume are carried out on a one-time, periodic or permanent basis. Outsourcing of products for manufacturers of furniture or other equipment from MDF, chipboard, OSB is possible.

Advantages of cooperation with the company

The presence of a modern production base, a fleet of machines and other equipment allows you to perform the entire cycle of work. That is, in addition to cutting, precise adjustment of products in shape, size, grinding or other finishing can be carried out.

The order is placed online using a special form on the company’s website. You can also call by phone and discuss all the details of cooperation.

An important characteristic of the work of “Easy Spray” is precise planning, optimal options for processing the workpiece, when the amount of waste is reduced, the order fulfillment time is reduced. At the same time, compliance with the design requirements and conditions of the customer is fully guaranteed.

The cost of services is optimal, taking into account the quality and speed of order fulfillment.